Application of Servomate Servo Voltage Stabilizer for Injection Molding Machines

Optimize Injection Molding Machine Performance with Servomate Servo Voltage Stabilizers

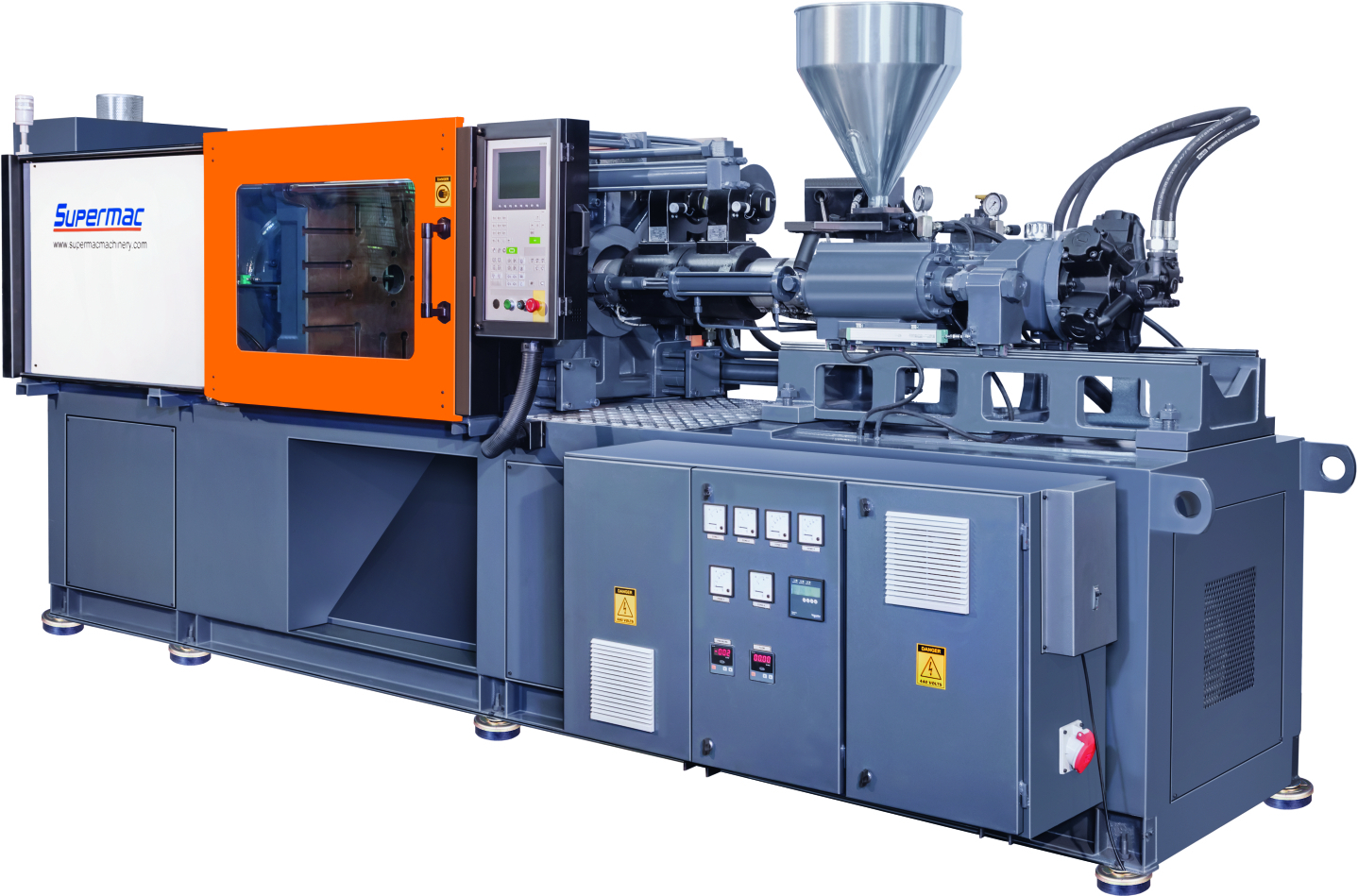

Injection molding machines are crucial in industries such as automotive, consumer goods, packaging, and electronics for the production of high-precision molded components. These machines rely heavily on stable power to maintain accurate temperature control, precise injection pressure, and consistent molding cycles. Voltage fluctuations, including surges, dips, or spikes, can significantly affect the machine’s performance, resulting in poor-quality products, equipment wear, and higher production costs. The Servomate Servo Voltage Stabilizer ensures that your injection molding machines receive a steady voltage, protecting them from power irregularities and maximizing production efficiency.

Why Do Injection Molding Machines Need a Servo Voltage Stabilizer?

Injection molding machines use high-powered motors, precise controllers, and temperature regulation systems. These machines are vulnerable to the effects of voltage instability, which can lead to:

⚠ Inconsistent molding quality and defective products

⚠ Frequent equipment malfunctions and downtime

⚠ Overheating of motors and loss of precision

⚠ Reduced machine lifespan and increased maintenance costs

⚠ Increased energy consumption and higher utility bills

A Servomate Servo Voltage Stabilizer ensures consistent voltage supply, protecting your injection molding machine from these risks, improving output quality, and minimizing downtime.

Key Benefits of Servomate Servo Voltage Stabilizer for Injection Molding Machines

✅ 1. Protects Injection Molding Machines from Voltage Fluctuations

Injection molding machines are sensitive to voltage variations, which can lead to machine damage, overheating, and loss of precision. A Servomate Servo Voltage Stabilizer ensures a steady voltage supply, protecting your motor, controller, and heating elements from voltage surges and dips, ensuring the longevity of your equipment.

✅ 2. Enhances Molding Quality and Consistency

Fluctuating voltage can cause temperature instability and inconsistent injection pressure, leading to product defects such as warped or misaligned components. By maintaining a stable voltage to your injection molding machine, a Servomate Servo Voltage Stabilizer ensures consistent molding cycles, improving the quality and precision of your molded products.

✅ 3. Extends the Life of Injection Molding Equipment

The delicate electronics and motors in injection molding machines are at risk of wear and tear caused by voltage fluctuations. The Servomate Servo Voltage Stabilizer provides constant voltage regulation, preventing damage and premature aging of key components, helping to extend the machine’s service life and reduce maintenance costs.

✅ 4. Reduces Downtime and Operational Interruptions

Voltage instability is a major cause of unscheduled downtime, resulting in delays and higher production costs. A Servomate Servo Voltage Stabilizer ensures continuous operation by quickly correcting any voltage fluctuations, preventing unexpected power cuts and maintaining uninterrupted production.

✅ 5. Increases Energy Efficiency and Lowers Power Costs

Injection molding machines require a significant amount of energy, and voltage fluctuations can lead to inefficient power consumption, increasing electricity bills. A Servomate Servo Voltage Stabilizer ensures that the voltage supplied to the machine is optimized, helping to reduce energy waste and improve the overall energy efficiency of your operation.

✅ 6. Ideal for High-Volume Production Runs

Whether you are running a high-volume injection molding operation or a small-scale production setup, the Servomate Servo Voltage Stabilizer provides optimal voltage regulation, ensuring that your machines operate consistently and efficiently regardless of power grid instability.

✅ 7. Suitable for All Types of Injection Molding Machines

Servomate Servo Voltage Stabilizers are suitable for various injection molding machines, including:

✔ Hydraulic Injection Molding Machines – Ensures stable voltage for efficient hydraulic press operation

✔ Electric Injection Molding Machines – Maintains voltage consistency for high-precision control systems

✔ Hybrid Injection Molding Machines – Provides optimal power supply for both electric and hydraulic systems

Why Choose Servomate Servo Voltage Stabilizer for Injection Molding Machines?

✔ Advanced Microcontroller-Based Technology – Provides accurate voltage regulation for injection molding systems

✔ Instant Voltage Correction – Quickly addresses voltage fluctuations to keep machines running without interruptions

✔ Heavy-Duty Construction – Built to handle the high-power demands of injection molding operations

✔ Oil-Cooled & Air-Cooled Models – Ideal for continuous operations in high-performance environments

✔ Custom Voltage Solutions – Tailored to meet the specific voltage needs of different types of injection molding machines

✔ Reliable After-Sales Support – Technical support and maintenance services available for efficient operation

Optimize Your Injection Molding Machine Performance with Servomate Servo Voltage Stabilizers

Ensure consistent molding quality, reduce downtime, and extend the lifespan of your injection molding machines with the Servomate Servo Voltage Stabilizer. Protect your equipment from voltage fluctuations and improve energy efficiency for a more cost-effective production process.

📞 Contact Us Today for the Best Servo Voltage Stabilizer for Injection Molding Machines!