Application of Servomate Servo Voltage Stabilizer for CNC Waterjet Cutters

Optimizing CNC Waterjet Cutting with Servomate Servo Voltage Stabilizers

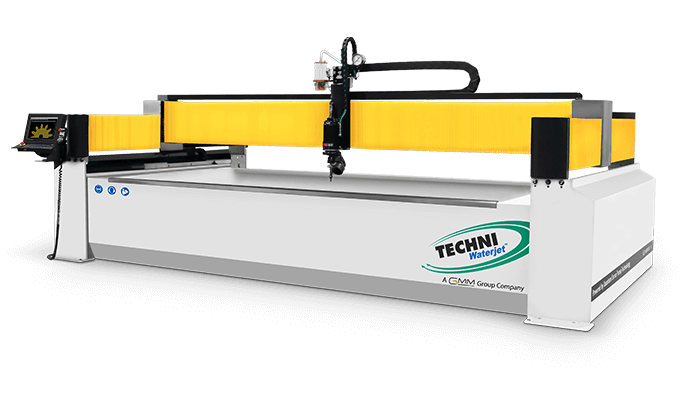

CNC Waterjet Cutters are widely used for precise cutting of a variety of materials, including metal, stone, glass, and composite materials. These machines require a stable and consistent power supply to ensure the accuracy and efficiency of the cutting process. Voltage fluctuations, surges, and dips can cause inconsistent water pressure, poor cutting quality, and even damage to sensitive components like motors and control electronics. The Servomate Servo Voltage Stabilizer is designed to deliver constant voltage, ensuring optimal machine performance and precision cutting.

Why Do CNC Waterjet Cutters Need a Servo Voltage Stabilizer?

CNC Waterjet Cutters are equipped with high-power pumps, motors, and sophisticated control systems, all of which require a steady voltage to function properly. Voltage instability can lead to:

⚠ Inconsistent cutting performance and poor quality edges

⚠ Overheating and damage to the pump motor and control systems

⚠ Erratic water pressure and cutting misalignment

⚠ Frequent machine breakdowns and increased downtime

⚠ Higher maintenance and operational costs

A Servomate Servo Voltage Stabilizer for CNC waterjet cutters ensures consistent voltage, helping to optimize cutting precision, extend equipment life, and reduce overall operating costs.

Key Benefits of Servomate Servo Voltage Stabilizer for CNC Waterjet Cutters

✅ 1. Protects High-Powered Motors and Pumps from Voltage Instability

CNC Waterjet Cutters rely on high-powered pumps and motors that are highly sensitive to voltage fluctuations. A Servomate Servo Voltage Stabilizer ensures constant voltage supply, protecting these vital components from damage and ensuring smooth operation.

✅ 2. Ensures Consistent Cutting Quality and Accuracy

Voltage instability can cause inconsistent water pressure and misaligned cutting, resulting in poor-quality edges and wasted materials. A Servo Voltage Stabilizer for CNC waterjet cutters maintains a stable voltage, guaranteeing consistent cutting quality and precise results.

✅ 3. Reduces Machine Downtime and Lower Maintenance Costs

Frequent voltage fluctuations can lead to machine breakdowns and increase the need for repairs and maintenance. A Servomate Stabilizer ensures stable voltage, minimizing downtime and reducing the overall maintenance and repair costs for CNC waterjet cutters.

✅ 4. Extends the Life of Waterjet Cutter Components

Voltage instability can cause overheating and damage to sensitive components such as motors, control systems, and pumps. A Servomate Servo Voltage Stabilizer provides voltage protection, extending the lifespan of these components and reducing the need for replacements.

✅ 5. Improves Energy Efficiency and Reduces Power Loss

Voltage fluctuations lead to inefficient power consumption, resulting in higher energy costs. A Servomate Servo Voltage Stabilizer optimizes the voltage supply, ensuring energy-efficient operation and helping to lower electricity bills for CNC waterjet cutting operations.

✅ 6. Prevents Overloading and Electrical Failures

Voltage surges or drops can cause overloading of electrical components in CNC waterjet cutters, leading to electrical failures. A Servomate Servo Voltage Stabilizer provides overload protection, ensuring the safe operation of the machine and preventing electrical malfunctions.

✅ 7. Suitable for Various CNC Waterjet Cutting Applications

Servomate Stabilizers are ideal for different types of CNC waterjet cutting systems, including:

✔ Abrasive Waterjet Cutters – Stabilizes power for consistent cutting performance with abrasive materials

✔ Pure Waterjet Cutters – Ensures steady voltage for high-precision cutting of soft materials

✔ 5-Axis CNC Waterjet Systems – Protects multi-axis control systems and ensures accurate and complex cuts

✔ Large Format Waterjet Cutters – Provides consistent voltage for large-scale cutting operations

Why Choose Servomate Servo Voltage Stabilizer for CNC Waterjet Cutters?

✔ Advanced Microcontroller-Based Technology – Provides high-precision voltage regulation for CNC waterjet systems

✔ Instant Voltage Correction – Corrects voltage fluctuations instantly to ensure continuous cutting accuracy

✔ Heavy-Duty Construction – Designed for high-power CNC waterjet applications

✔ Oil-Cooled & Air-Cooled Models – Suitable for high-temperature, heavy-duty cutting environments

✔ Custom Voltage Solutions – Tailored to meet the voltage requirements of various CNC waterjet cutters

✔ Reliable After-Sales Support – Technical support and maintenance services provided for all installations

Maximize Your CNC Waterjet Cutter’s Performance with Servomate Servo Voltage Stabilizers

Ensure optimal cutting precision, reduce downtime, and extend the service life of your CNC waterjet cutters with a Servomate Servo Voltage Stabilizer. Enhance cutting accuracy, improve energy efficiency, and lower maintenance costs with our advanced voltage stabilization technology.

📞 Contact Us Today for the Best Servo Voltage Stabilizer for CNC Waterjet Cutters!

.