Application of Servomate Servo Voltage Stabilizer for Compression Molding Machines

Enhance Compression Molding Machine Performance with Servomate Servo Voltage Stabilizers

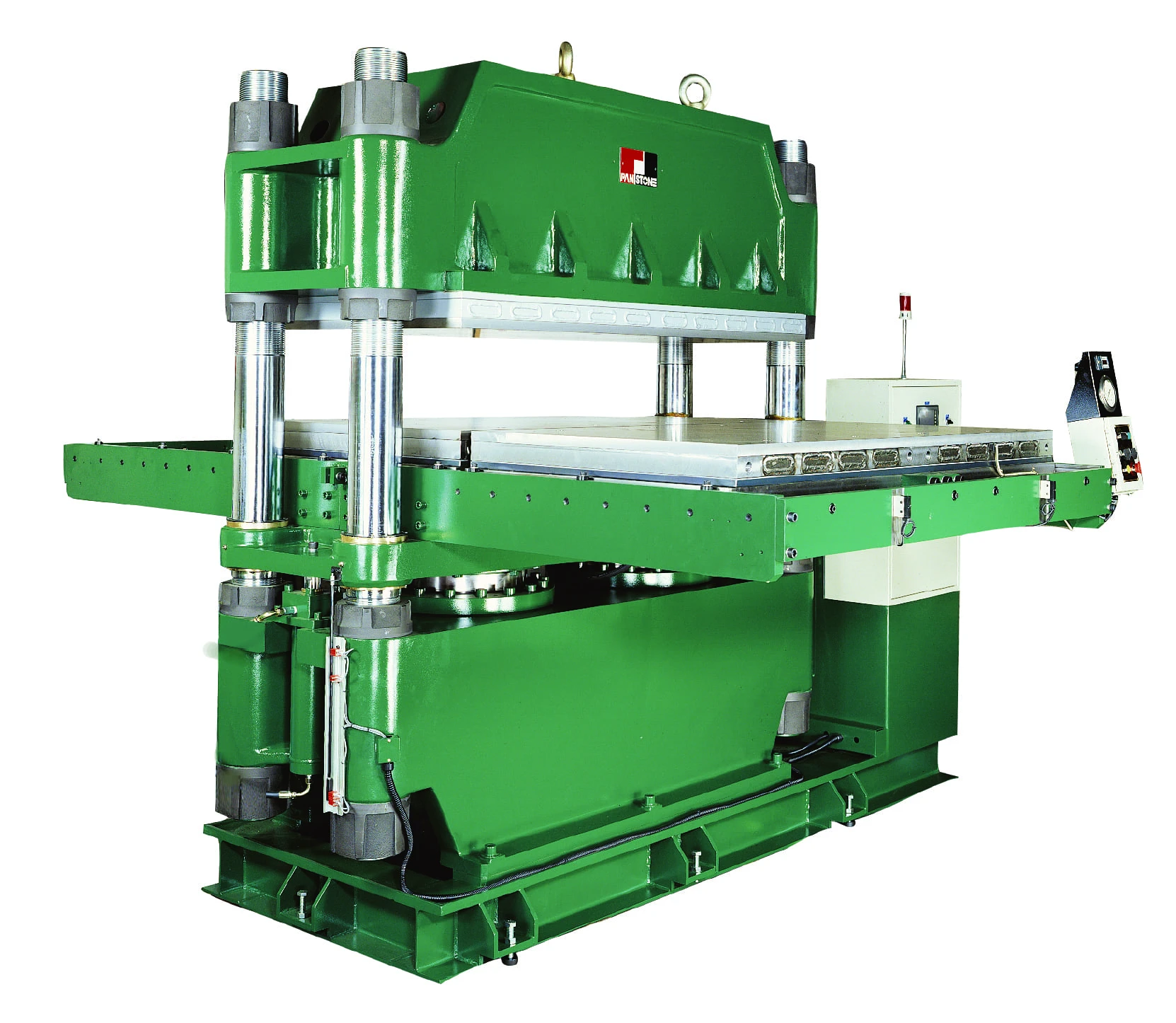

Compression molding machines are critical in manufacturing rubber, plastic, and thermosetting materials used in industries like automotive, electronics, and consumer goods. These machines rely on precise control of temperature, pressure, and speed to produce high-quality, durable components. Voltage fluctuations, such as dips, surges, or spikes, can significantly impact machine performance, leading to poor product quality, equipment damage, and production delays. The Servomate Servo Voltage Stabilizer provides a consistent voltage supply, ensuring that your compression molding machine operates efficiently, improving product consistency and machine longevity.

Why Do Compression Molding Machines Need a Servo Voltage Stabilizer?

Compression molding machines are sensitive to voltage instability. Even small fluctuations in voltage can lead to:

⚠ Inconsistent product quality and defective molded parts

⚠ Frequent breakdowns and downtime

⚠ Motor damage and overheating

⚠ Reduced efficiency and increased energy consumption

⚠ Shortened lifespan of critical components

A Servomate Servo Voltage Stabilizer ensures that your compression molding machines receive a stable voltage, preventing these issues and providing a reliable power source for efficient production and product quality.

Key Benefits of Servomate Servo Voltage Stabilizer for Compression Molding Machines

✅ 1. Protection Against Voltage Fluctuations

Compression molding machines are high-power equipment with sensitive electronics and motors. Fluctuating voltage can cause damage to heating elements, pressure controllers, and temperature sensors. A Servomate Servo Voltage Stabilizer provides stable voltage regulation, preventing damage to critical components and ensuring that the machine operates smoothly at all times.

✅ 2. Consistent Product Quality

Voltage instability can lead to temperature variations, causing inconsistent material flow and defective molded parts. The Servomate Servo Voltage Stabilizer ensures precise control over temperature and pressure, maintaining consistent product quality with every molding cycle.

✅ 3. Reduces Machine Downtime

Voltage fluctuations are a leading cause of unplanned machine downtime. A Servomate Servo Voltage Stabilizer provides immediate voltage correction, ensuring that your compression molding machine operates without interruptions, improving uptime and overall productivity.

✅ 4. Protects Equipment and Extends Lifespan

The motors and electronic components in compression molding machines can wear out quickly due to voltage surges and dips. The Servomate Servo Voltage Stabilizer ensures that your equipment is protected from these fluctuations, helping to extend the lifespan of your machine and reduce the need for frequent repairs.

✅ 5. Enhances Energy Efficiency

Voltage fluctuations can lead to inefficient power usage, driving up energy costs. The Servomate Servo Voltage Stabilizer optimizes energy consumption, ensuring that your compression molding machine receives the correct voltage, resulting in lower energy bills and improved operational efficiency.

✅ 6. Suitable for All Compression Molding Applications

Whether you are producing rubber parts for automotive applications or plastic components for consumer electronics, the Servomate Servo Voltage Stabilizer is adaptable to all types of compression molding machines. It provides a steady voltage supply to meet the specific power needs of different machine models.

✅ 7. Ideal for Continuous Production

Compression molding is a high-speed, high-demand process requiring uninterrupted operation. The Servomate Servo Voltage Stabilizer ensures that the machine receives constant voltage, helping to maintain efficiency and quality throughout long production runs.

Why Choose Servomate Servo Voltage Stabilizer for Compression Molding Machines?

✔ Microcontroller-Based Technology – Precise voltage regulation for optimal performance of compression molding equipment

✔ Instant Voltage Correction – Quickly addresses voltage surges and dips, minimizing downtime

✔ Heavy-Duty Construction – Built for high-power operations and continuous production environments

✔ Oil-Cooled & Air-Cooled Models – Ideal for handling the high-temperature conditions in compression molding processes

✔ Custom Voltage Solutions – Tailored to meet the specific voltage requirements of compression molding machines

✔ Reliable After-Sales Support – Dedicated technical support and maintenance services

Boost Your Compression Molding Machine Performance with Servomate Servo Voltage Stabilizers

Ensure consistent product quality, reduce downtime, and extend the lifespan of your compression molding machine with the Servomate Servo Voltage Stabilizer. Safeguard your equipment from voltage fluctuations, optimize energy efficiency, and maintain seamless operations in your molding process.

📞 Contact Us Today for the Best Servo Voltage Stabilizer for Compression Molding Machines!